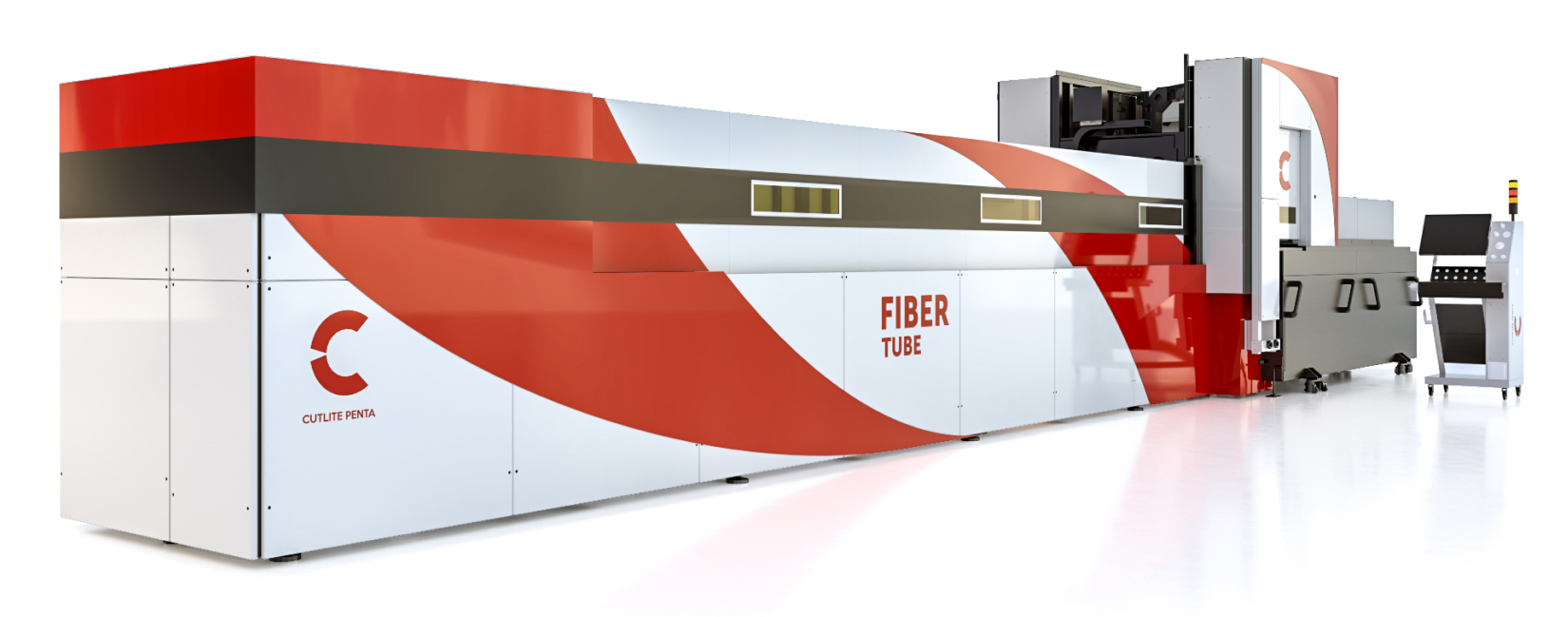

TUBE

Uncompromising performance

Power up to

6kW

Tube Cutting up to

305mm

Tube Cutting Laser Machine

TUBE is the result of CUTLITE PENTA’s long and consolidated experience in the field of laser machines and represents the future of laser technology applied to metal tube cutting. The TUBE system is an automatic processing system that allows obtaining a finished part, complete with all the cutting operations required, in a single machining cycle.

This approach represents a technological and productive leap compared to traditional methods, which require several steps on different machining centres to subsequently carry out the required cutting, deburring, drilling, end trimming, interlocking and special CNC machining. This is achieved thanks to the speed, quality, accuracy, flexibility and reliability of laser technology. The system allows the automatic machining of round, square, rectangular tubes and open profiles.

CONFIGURATOR

TUBE Head

TUBE systems boast a unique cutting head, the brainchild of our research and development department. The essential design, optimized to minimize maintenance, is distinguished by the completely sealed optical unit, which guarantees durability over time. The compact and modular configuration of the Tube head is distinguished by the simplicity of the consumables.

Laser sources

Fiber laser sources provide extensive versatility and make it possible to cut a multiplicity of metal types. Developed as a single system, it can be paired with a wide variety of optical fiber diameters. High efficiency, excellent beam quality and low power consumption are all hallmarks of the source. The source is housed in a NEMA 12 cabinet which is conditioned and sealed so that it can operate even in the harshest of environments. The high degree of reliability of these sources also ensures particularly low maintenance costs.

Automatic step LOADER

- Maximum capacity 6 tubes having a ø 305mm diameter or maximum side 220mm

- Automatic loading of tubes from ø 20mm - up to ø 305mm

- Automatic loading lengths from 1500mm to 6500mm, which can be increased on request

- Sliding surfaces entirely covered in plastic material to avoid damaging and scratching delicate tubes

- Possibility of mounting on the operator or rear side

Automatic bundle LOADER

- Loading Maximum 2000/4000Kg

- Automatic loading of Ø 20mm (**) tubes max. ø 220mm (**), which be reduced on request

- Automatic loading lengths from 1200mm to 6500mm, which can be increased on request

- Measurement of tube length before loading into the machine

- Sliding surfaces entirely covered in plastic material to avoid damaging and scratching delicate pipes

hardware solutions

Smart Weld

It allows detecting the position of the weld bead (both external and internal) before the bar is loaded into the machine, while the previous bar is being processed.

Camera

A position camera that enables remote monitoring and viewing of machine operation.

Tube Size Detection

Tube size optical detection sensor.

Automation

The various automation options allow the optimization of the work phases, without significant idle times for loading and unloading operations.

Smart Mandrel (optional)

Electro spindle with a 10-bay automatic tool change device, to execute flow drilling and tapping up to M12.

Smart Cleaning (optional)

Device for collecting internal scraps on a round tube.

Software

Simple and intuitive cutting-edge front-end software, designed to guarantee the highest level of versatility and customisation.

Laser cutting has never been so easy.

Smart manager plus

An innovative software for machine management and supervision. With Internet access, the system can be monitored via remote assistance using TeamViewer.

Smart Composer

Cutlite Penta’s revolutionary new software interfaces seamlessly with the machine’s numerical control and smart manager front-end software.

Samples

Technical Features

| MODEL | ROUND FORMAT | SQUARE/RECTANGULAR FORMAT | TUBE WALL THICKNESS |

| TL 120 | min 12 mm max 120 mm ø | min 12 mm max 120 mm | 6 mm |

| TL 150 | min 15 mm* max 152,4 mm ø | min 15 mm* max 152,4 mm | 8 mm |

| TL 220 | min 20 mm* max 220 mm ø | min 20mm* max 160/220 mm* | 10 mm |

| TL 305 | min. 20 mm* max. 305 mm ø | min 20 mm* max 220 mm | 10 mm |

| LASER POWER |

| 1000 W |

| 2000 W |

| 3000 W |

| 4000 W |

| 6000 W |

| LOADABLE/UNLOADABLE BAR LENGHT |

| 3000mm – 6000mm |

| 6000mm – 1200mm |

Choose the Cutlite Penta laser solution that best meets your business requirements

Our team of experts is ready to help you and show the most suitable solution for your needs.

- Phone

- +39 0574 874301