Efficiency and productivity are increasingly crucial factors for companies operating in the metal industry. The current market demands high standards of quality and reduced production times, forcing companies to evolve rapidly to keep up with these requirements. Fiber laser cutting machines meet these needs with cutting-edge technologies and high-power performance.

However, it is equally important to optimize the workflow to ensure excellent product quality while maintaining sustainable operational processes for the company. Here’s how fiber laser systems can optimize the production process and what aspects to consider to use them most effectively.

The Advantages of Fiber Laser Technology for Optimizing Production

Fiber laser cutting machines for metal offer many advantages over traditional technologies, such as plasma cutting or CO2 lasers. One of the main benefits is greater energy efficiency: the fiber laser consumes less energy, reducing operational costs and optimizing production. Additionally, it ensures superior cutting quality with extremely high precision, producing cleaner edges without the need for finishing, thus reducing the overall production time.

Another advantage of fiber laser technology is the repeatability of the process, thanks to the incredible stability of the laser beam emitted from the optical fiber.

Thanks to linear motors and advanced motion systems, high-tech fiber laser cutting machines enable faster processing while maintaining consistent quality over time.

This results in better management even for large-scale productions and ensures high-quality standards for customers, benefiting the company’s reputation. Finally, the reduced maintenance and long lifespan of optical and mechanical components make fiber laser technology highly reliable and cost-effective in the long run.

The exceptional power performance achieved in terms of power, such as with the Cutlite Penta 50 kW fiber laser systems, now offers previously unimaginable capabilities even for thicker materials, allowing companies in new sectors to choose this technology over more expensive and inefficient cutting systems. Given these tangible advantages, innovative solutions are available to further optimize the workflow. What are they?

Solutions for Optimizing Cutting Processes

Adopting a fiber laser cutting system is an important first step towards a more efficient production process. However, to achieve maximum performance, it is essential to integrate advanced and cutting-edge solutions. Let’s explore some of the main strategies and technologies available:

Automated Loading and Unloading

One of the main causes of extended production times is the loading and unloading of materials. Handling the parts is often difficult and leads to downtime, interrupting the production cycle. A solution to this problem is the integration of automated loading and unloading systems, which improve productivity by reducing the downtime between operations. Automating sheet changes and the positioning of parts to be cut not only speeds up production and optimizes laser machine usage, but also provides several other benefits, such as:

- Reduced risk of damaging the material

- Lower risk of injuries for operators

- Reduction in repetitive tasks

- More productive use of resources

- Greater predictability of time and costs

Warehouse Automation

Similar to loading and unloading systems, an automated warehouse system reduces the time spent handling raw materials and semifinished goods. The integration with production management software enables intelligent material retrieval, minimizing time waste and improving operational continuity. Naturally, this system must be implemented with consideration for the location of machines and raw materials within the company, as well as the operational flow. That’s why, in this case, the option to use customized configurations and systems is definitely an advantage to consider.

Reliability and Functionality of Systems

Among the factors that most impact a company’s operations, the quality of the technologies used is of primary importance. Not all fiber laser systems ensure the same efficiency and reliability. The efficiency of the laser system depends on the construction quality of the machine and the performance the technology is capable of delivering.

The most advanced solutions, such as Cutlite Penta systems, feature high-performance linear motors that ensure precision and constant speed, as well as cutting-edge technologies like the EVO 3 cutting head, patented by the company, capable of supporting extremely high-power levels up to 50kW. The use of state-of-the-art technologies ensures production continuity, reduces machine downtime costs, and guarantees excellent final product quality.

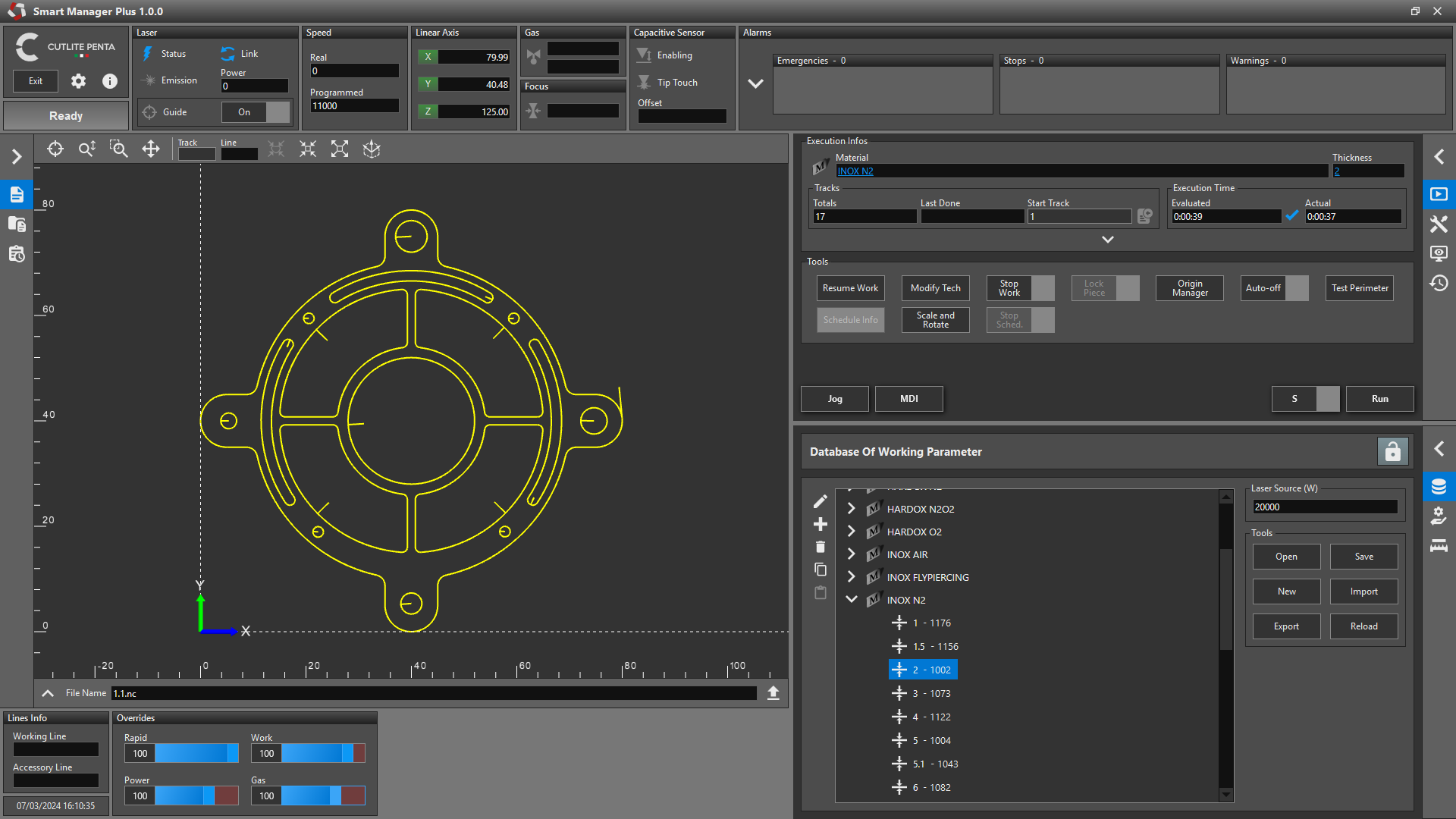

Advanced Control Software

In the operation of a laser system, the control software plays a crucial role by reducing the possibility of errors and simplifying operations. Advanced software enables reduce setup times and ensures optimal performance, optimizing the entire workflow. Integration with business management systems also allows real-time monitoring of production and improves work scheduling. Finally, an intuitive interface makes it easier to carry out each operation and quickly customize cutting parameters.

Nesting for Material Optimization

To save time and materials in laser processing, it is essential to arrange the parts to be cut as compactly as possible on the sheet, minimizing waste. Using advanced software for nesting management allows for optimal placement of parts, improving material yield and reducing production costs. Another significant advantage of fiber lasers is the ability to perform common cutting, which is not possible with plasma systems.

Adjustment of Parameters in Laser Cutting

To achieve optimal results with a fiber laser cutting machine, it is also essential to accurately adjust the processing parameters. Each parameter directly impacts the laser’s performance and the cutting quality, so it must be carefully considered. The main processing parameters to consider include:

- Beam polarization: affects the energy distribution and the laser’s ability to uniformly penetrate the material.

- Wavelength: fiber lasers generally operate at 1.06 μm, the ideal wavelength for cutting metallic materials as it ensures high energy absorption and precise cutting.

- Power and intensity: These must be set according to the material thickness and cutting speed. Higher power allows cutting thicker materials with straight edges.

- Cutting speed: Influences the finish of the cut. A speed that is too high can cause burrs, while a speed that’s too low can result in overheating and distortion.

- Working gas: the use of oxygen, nitrogen, or gas mixes (a combination of nitrogen and oxygen) affects the cutting type, quality, and cutting speed.

- Focal point: correct adjustment of the laser system’s focal point ensures a precise and uniform cut. The focus must be adjusted based on the material’s thickness and reflectivity.

- Material specifications: each metal has different characteristics that affect the cutting quality.

Understanding these parameters and their interaction allows for optimal configuration of the processes, avoiding damage to the laser system or material. Cutlite Penta technicians are capable of optimizing each parameter to ensure the highest quality processing.

Cutlite Penta Laser Systems: Automation and Efficiency for Outstanding Performance

Cutlite Penta fiber laser systems represent the highest expression of fiber laser technology for metal cutting, offering ultra high-power solutions designed for processing thick materials and large formats. Entirely manufactured at the company’s facility in Tuscany, these systems integrate proprietary high-tech cutting heads, ensuring uncompromising precision and reliability.

In addition, Cutlite Penta internally develops automated loading and unloading systems, which can be configured in-line or at 90°, and paired with vertical storage warehouses. These systems communicate directly with the laser machines to ensure a continuous and highly efficient workflow.

Laser Machine Hardware Accessories

To further enhance the performance of its laser cutting systems, Cutlite Penta offers a range of innovative hardware accessories. These advanced components help optimize operations by reducing downtime and increasing both quality and repeatability of the processes. Among them are:

- Automatic nozzle change: allows the machine to replace the nozzle without operator intervention, minimizing downtime.

- Positioning camera: enables remote monitoring and control of the machine’s operations.

- GASMIX: for mixing nitrogen and oxygen.

- Automation: a selection of features designed to boost production efficiency.

Each laser system is equipped with specific accessories tailored to the operations it is intended to perform.

Advanced Control Software

Cutlite Penta relies on cutting-edge software for the management and control of its laser machines, particularly:

- Smart Manager Plus: enables full supervision of the machine and all its parameters, managing power throughout the various cutting phases and the geometries of the object to be processed.

- All Cutlite Penta systems are accessible for remote support via the Internet and TeamViewer.

The integration of advanced laser systems with built-in automation into the production line is key to achieving an efficient and high-performance manufacturing process. Alongside the advantages of fiber laser systems, Cutlite Penta offers dedicated, skilled, and timely support, as well as customized configurations tailored to meet the specific needs of your business.

Discover all the laser solutions for your production needs or contact us for more information.