The success of the laser cutting machines for metals in the industrial panorama has revolutionised the production dynamics. The guaranteed efficiency of the laser cutting systems for sheet metal and tubes has ensured the increase in the productivity of companies by reducing costs and delivery times. By rendering more competitive the industries that have adopted lasers, the quality in metal processing has also increased. How can the laser cutting machines guarantee these advantages?

How a laser cutting machine for metals works

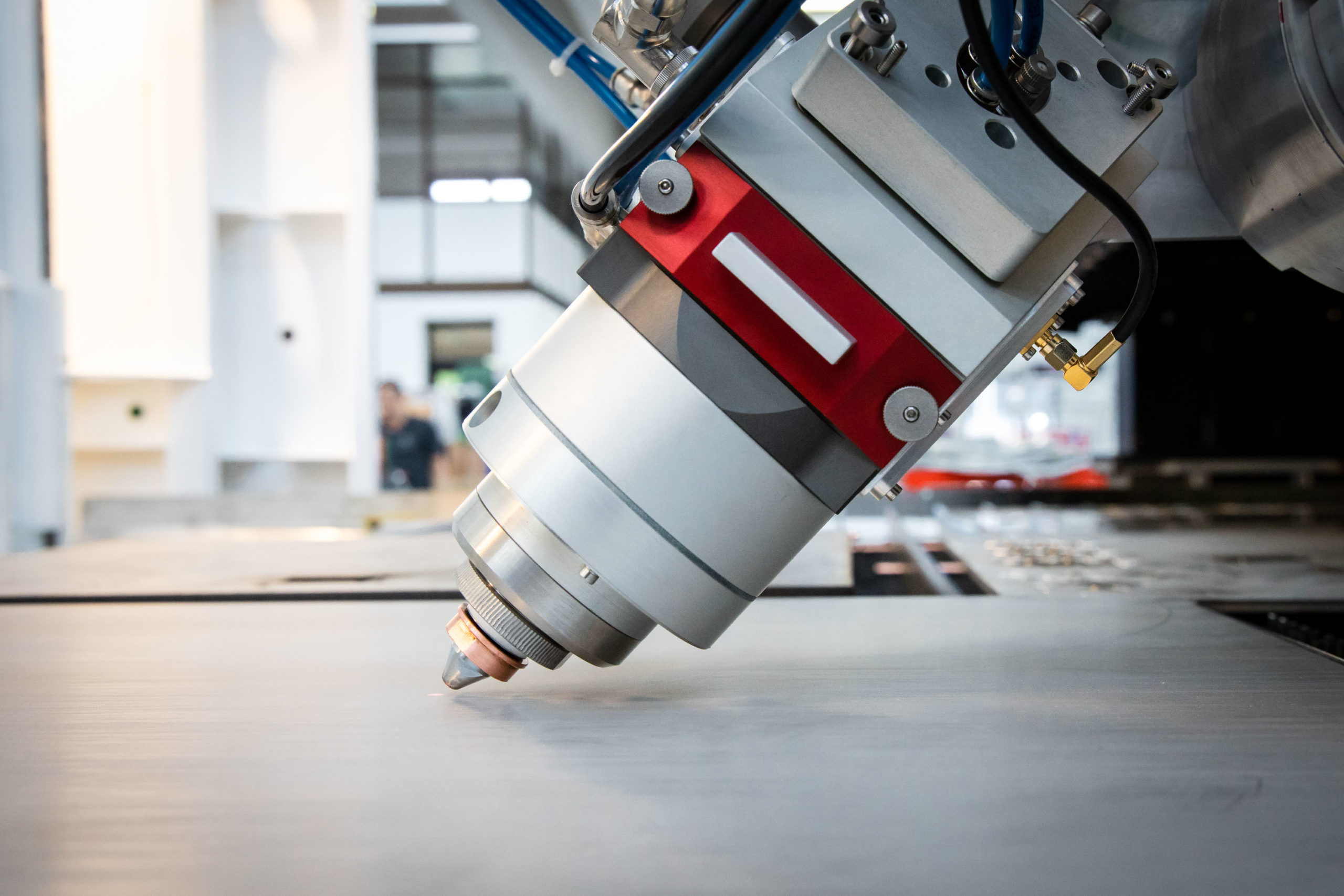

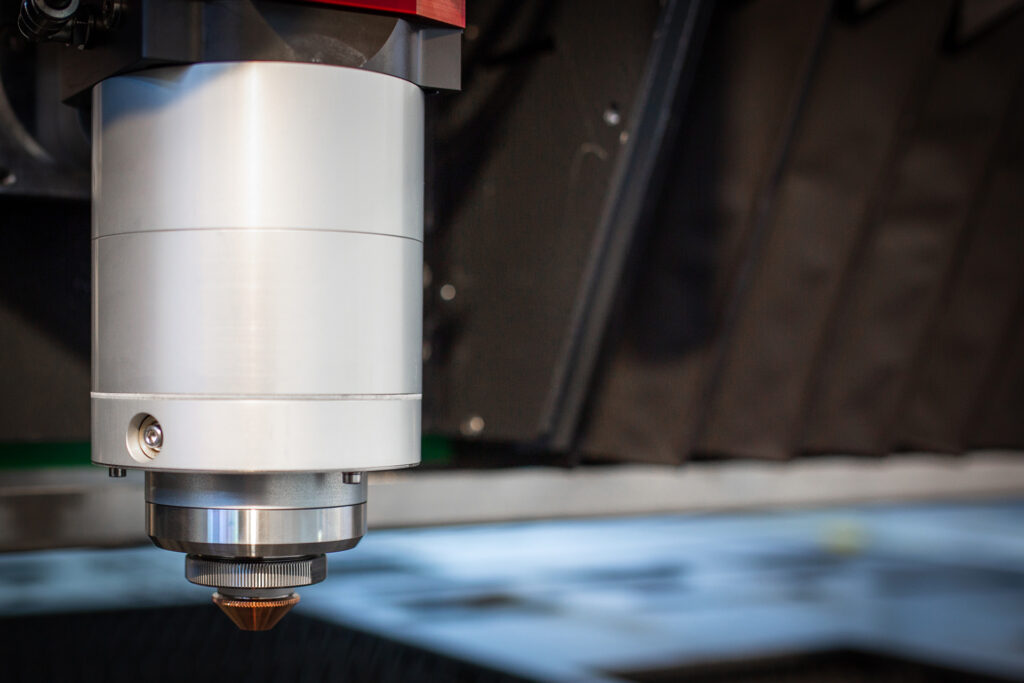

To understand the impact of a laser cutting system on the productivity it is necessary to start with the operation. The laser cutting machines for metals can work both individually and integrated to complex productive chains: for example combined to loading/unloading systems or to other machines that perform different operations, with perfect integration into the production line. All laser cutting systems are composed by a cutting head installed on a robotised mechanical arm or on an axis system. The numeric control allows the set-up of the laser operation that takes place inside a specially shielded structure. The structure of the operation level varies depending on the piece as well as on the fixing system. Particularly it is possible to define:

Metal laser cutting in 2D

The machines for metal laser cutting in 2D are used to process sheet metal and work with two axes x and y + z for the displacement of the cutting head. They are mostly used in combination with other systems and feature automatic loading/unloading.

Metal laser processing in 3D

The laser cutting systems in 3D are used to process sheet metal already shaped in die forming, folding and deep drawing processes. In this case they are machines designed to operate on 5 axes or with a robot on three-dimensional structures. Naturally they can also be used for 2D operations.

Laser cutting of tubes

The machines for the laser cutting of tubes can be used to process thin metallic tubes up to a thickness of 10mm, with the appropriate modulation of the laser beam. The tube is positioned on a mandrel and can be cut and processed with boring and profiling in a single phase, thus optimising production times.

Additionally, metal laser cutting machines are divided in:

- TheCO2laser cutting, with wavelength of 10 µm and based on a gaseous mixture of CO2, Nitrogen, Hydrogen and Helium, is electrically excited.

- Fibre laser cutting, with wavelength of 1µm and based on laser supplied by diodes and transported by special quality fibre optics.

Advantages of laser cutting for metal processing

The reasons for preferring the laser cutting systems for metals instead of the traditional processing are multiple, both from the economic point of view and for the production quality. Particularly, the laser processing machines can offer:

Maximum versatility

One of the advantages of laser is the possibility of performing customised and also very complex processing in short times. This has allowed companies to achieve previously unthinkable results and expand production with highly customised products.

Extraordinary accuracy

The laser beam offers a cutting and processing accuracy not attainable with other systems. The quality of the cut pieces is therefore extremely high and does not require further finishing. The advantage is double, due to savings in the time and costs for achieving the final quality of the product.

Production speed

The times needed for laser processing are extremely reduced because the laser beam is capable of performing complex cuts and processing in a few minutes. The processing speed comes together with time savings in tool changing and finishing operations that can be dismissed.

Low power consumption

The laser cutting machines for metals offer the advantage of low consumption in comparison with other processing methods. An important feature for reducing production costs andimpacts on the environment.

Safety for the operators

The laser cutting operator works essentially with numeric control, without the need for manual processing and tool changing. This is an outstanding advantage for the safety in the workplace.

Reduced risk of damage

Because it processes pieces without mechanical contact the laser cutting systems for metals ensure better processing control, thus reducing to a minimum the risk of damaging the material. The result is an expressive reduction in production costs, as well as the absence of rejections and therefore scrapped material.

Which type of metal laser cutting offers more advantages?

The machines with CO2 laser technology have represented for many years the only kind of laser metal cutting available; however, in recent years, the introduction of fibre laser systems has brought incredible advantages, which have by now fully replaced the obsolete CO2 technology. Particularly, the fibre laser offers:

Better performance

The fibre laser beam guarantees, besides the power, higher performance concerning both speed and cutting accuracy.

Greater efficiency

The efficiency of a cutting machine with fibre laser can be much higher than a CO2 laser system thanks to a lower power consumption.

Processing and boring even with high thickness

The fibre laser concentrates the maximum power on an infinitesimal diameter allowing boring with reduced dimensions also with high thickness up to 50mm.

Less maintenance

The maintenance costs of a fibre laser machine are significantly lower with respect to all other metal processing systems.

Laser cutting also of delicate metals

The 10 times lower wavelength of the fibre laser beam also allows the cutting and processing of metals such as copper and brass, not recommended for processing with CO22 laser.

Which is the cutting power of fibre laser on metals?

Cutlite Penta has produced and marketed for the first time in Italy and in Europe machines with fibre laser for cutting metals up to 30 kW of power. All Cutlite Penta machines for the laser cutting of sheet metal and tubes are designed and built internally also with customised configurations. We additionally offer a technology with linear motors that is more efficient and compact regarding all other systems present in the market, with higher performance concerning power, speed and accuracy.

Find more about our laser cutting machines for metals or contact us to receive further information.